SolidWorks Training Center in Indore

- Real-Time Experts Sessions

- LIVE Project

- Certification

- Affordable Fees

- Flexibility

- Placement Support

Solidworks is a computer-aided design (CAD) and computer-aided engineering (CAE) software tool developed in 1993 at MIT and Marketed by Dassault Systems, which is used by millions of engineers across the globe.

SolidWorks is a solid modeling software used to determine the geometry of the model and is widely used by more than 3,073,600 product designers and engineers worldwide, across 230,400 organizations, for developing coolest gadgets to innovations that deliver a better tomorrow.

Achieve your goal with a proficient Solidworks training center in Indore, Tech Cluster is an institute with majority of industry experts as faculties. We do not focus only on practical experience but also prepare students to face interviews, which can be beneficial for the career. We cover the course in such a way that basics and advance level is served well with all important factors/tips & tricks of SolidWorks Training. Join our SolidWorks training center in Indore and across the India for online certification courses and programs via offline with job placements. Give wings to your career in the field of Mechanical, Automobile or Aeronautical designing engineering with Tech Cluster Designwala.

SolidWorks Course Highlights:

Solidworks Foundation :

- Basic & Advance Sketching

- Part Modeling

- Assembly

- Advance Assembly Design

- Creating Manufacturing Drawing

- Sheet Metal

- Surfacing

Solidworks Advanced :

- AutoCAD to Solidworks tools

- Simulation Express

- Weldment

- Mold (Core & Cavity)

- Photo works Essential

- SOLIDWORKS Routing

- SOLIDWORKS Simulation

Duration :

- 45 Hours Theory

- 45 Hours Practical

- 20 Hours Project work

Duration :

- 45 Hours Theory

- 45 Hours Practical

- 20 Hours Project work

Foundation Technical Features:

Basic & Advance Sketching

- Easy 2D Sketch creation & modification according to Design Intent

Smart Dimensions to create Linier, Angular, Aligned, Circular etc

- Creates Automatic Sketch Relations

Automatic Notification of Sketch States (Under Defined, Fully Defined & Over Defined)

- Automatic Sketch Operations to Repair Sketches

Creates Automatic Construction Entities like Center line, Center Marks, Points, Axis etc

- Automatic Highlights open Counters & Overlap Counters

Ready options to create Parabola, Hyperbola & Conics

Part modeling

- Improves visualization and communication

Data Migration tools to Import or Export

- Extrude, Loft, Standard hole wizard to generate most of the Mechanical Parts

All 3D models & 2D drawings are synchronized

- Different types of Geometry Patterns

Design Tables & Configuration to automate design

- Directly Modeling & Editing (Instant 3D)

Inbuilt Large Material Library

- Instantly Analyze Mass properties and Volume, Moments

of Inertia, CG, etc

Assembly

- Drag & Drop components to Assembly creates Automatic Relations

- Exploded views to Simplify Assembly Sequence

- Creates and Updates Automatic bill of Materials (BOM)

- Check Collision & Interference between Components

- Compare Alignment of Holes created using SolidWorks Hole Wizard

- Top down Approach helps to handle large Assemblies

- Skeleton Model Increases Flexibilities in Assembling the Parts

Create Manufacturing Drawings

- Creates 2D views as per International Standards like DIN, ASME, ANSI, ISO, GB etc.

- Automatic Projected, Section, Detailed, Alternate Position Views, etc.

- Drag and Drop Predefined Drawing views

- Creates Automatic & Associated BOM

- Optional First or Third Angle Projection view Orientation

- Automatic Scaling

- Verify Designs Against Company Standards

- Build Checks— Set up and save specific Design and Drafting Checks

- Check Specifically for fonts, dimension Arrows, Units, and other Documentation details

- Compare your Drawing to Past Results from Reviews of other Drawings

- Automated Revision Control

Sheet Metal

- Convert Imported CAD models to SolidWorks Sheet Metal Model

- Automatically Input your own bend radius, thickness, and K- Factor

- Generate Base, Edge, Miter, and Swept Flanges

- Generate bends, including Lofted Bends, Sketched Bends, and more

- Use Bend Tables for bend allowance/bend deduction

- Use Forming Tools to create features like ribs, louvers, lances, embosses

- Add weld details to sheet metal parts on models or drawings

- Automatically flatten parts to generate flat patterns (Development drawing)

Surfacing

- Create Complex & Esthetic Geometry using Swept, Planar & Ruled Surfaces

- Create Organic and Stylized Shapes using Boundary Surface, Surface Fill, Freeform Radiated Surface, M Surface

- Edit model using Move/Copy Face, Instant3D, Copy Surface, Replace Face, Healing, Knit, Trim, and Extend

- Surface analysis tools: Gaussian, Draft, Undercut, Thickness, Curvature, Min radius, Zebra Stripes, Deviation\ analysis, and Symmetry Check

- Geometry Import and Repair and Healing tools

Advance Technical Features:

AutoCAD to SOLIDWORKS tools

- Import options as a SolidWorks Drawing or SolidWorks Part

To read any modify 2D Data, Powerful tool Draft Sight

- Orienting and aligning 2D Sketches

Blocks and Mechanism for Sketches

- Convert all entity fully defined automatically

Simulation Xpress

- SolidWorks SimulationXpress is a first- Pass analysis tool

- Giving you the ability to do basic stress analysis on individual parts

- Quickly determine effects of force and pressure, and generate reports to document results

- Guided set up for Inexperienced Design Engineers

- Easy to Learn & Validate your part design

Weldment

- Work from a library of pre-defined structural shapes-Generate 3D sketch lines for structural profiles to follow.

- Automatically trim structural members at intersections-Add stiffening plates, gussets, and end caps.

- Add optional weld beads to the design-Generate drawings, BOMs, cut lists, and other manufacturing documentation

Mold (Core & Cavity)

- Geometry Import, Repair, and Healing tools

Draft Analysis, Undercut Analysis, and Thickness Analysis tools

- Parting line tools

Parting surface tools

- Automated “fill surface” capability for easy shutoff surface creation

Core and Cavity splitting tools

- 3D mold bases available on-line and directly from major mold suppliers

SolidWorks configurations to create customizable configurations of molds and mold components

- Compare Part tools to visually see in 3D what geometry was added or removed when design changes occur

Mold filling simulation with SW Plastics

- Production quality mold drawing creation tools

PhotoWorks Essentials

- Apply Appearances – Adjust elements of your model including color, texture, and illumination

Apply Scenes- Set and control the Background and surroundings

- Decals – for labeling, branding, stickers, instrument faces, etc

Integrated Preview – View your output in a preview window before fully rendering

- Rendering Options – Control output image resolution, animation frame rates, etc

Final Renderer – Generate detailed output after your preview

- Rendering Scheduler – Set up your rendering to run during off-hours

Rendering templates – Save rendering setting for later use to ensure consistent output

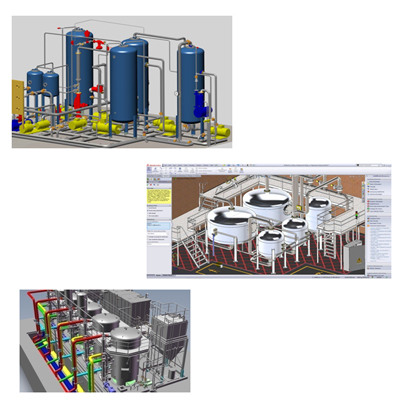

SOLIDWORKS Routing

- Create piping system designs with butt welded, socket welded, threaded and other connections

Create flexible or rigid tubing lines

- Automate placement of supports and hangers for all lines

Generate bend tables for tube routes to support manufacturing

- Calculate cut lengths for all pipe and tube runs

Auto- route pipe/tube paths through the design

- Ensure minimum bend radii in flexible tube systems

Export tubing/piping bend tables to CNC benders

- Automatically create bill of material (BOM), cut lists, bend tables and other mfg documentation Access a CAD library of piping and tubing components

SOLIDWORKS Simulation

- Component material , connections, and relationships defined

Products can be tested for strength and safety, and the kinematics fully analyzed

- A wide variety of geometry types are supported so you can simulate the real world performance Solid, thin-walled, and structural features for Complex geometry

- Beam element can be applied for structural analysis Shell elements can be applied for very thin parts like Sheet Metal

- Can create study for Part & Assemblies

Upcoming Batches

Certifications

SolidWorks Certification Training

About SolidWorks Certification Training in Indore at Tech Cluster