Brick Work Layout Training in India

- Real-Time Experts Sessions

- LIVE Project

- Certification

- Affordable Fees

- Flexibility

- Placement Support

Brick Work Layout is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Tech Cluster is an institute which provides Brick Work Layout training in Indore and offers chances to avail a great opportunity to learn the tool from basic to advanced level. Our expert faculties cover all the important factors of Brick Work Layout Training for beginners and intermediates. With our expert guidance students can excel in their career and earn good.

Course Highlights:

Brick Work Layout Foundation :

- What Is Brick?

- Technical Parts of Brick (Terms and Dimension)

- Bond Of Brick

- Orientation Of Brick

- Types Of Brick

- What Is AAC?

- Different Between Block and Brick

- Types Of Blocks

- Some Important Segment

Duration :

- 45 Hours Theory

- 45 Hours Practical

- 20 Hours Project work

Technical Features:

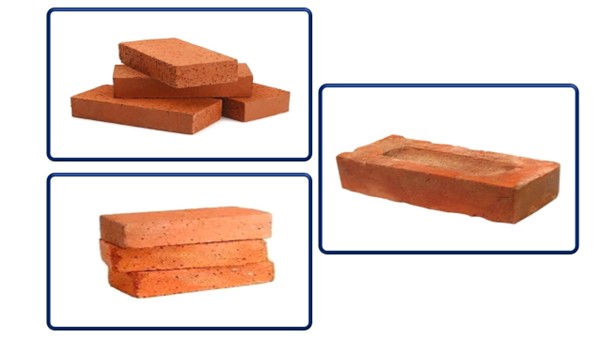

What Is Brick?

Rick masonry is a highly durable form of construction. It is built by placing bricks in mortar in a systematic manner to construct solid mass that withstand exerted loads. There are several types of bricks and number of mortars which can be used to construct brick masonry. The bond in brick masonry, which adheres bricks together, is produced by filling joints between bricks with suitable mortar. Special cautions shall be practiced while mortar is mixed and placed since it greatly affects the performance and durability of masonry structure.

· The walls of a building are generally constructed by bricks and the method of joining bricks in different fashions is called brick work.

· Brick is a basic building unit which is in the form of rectangular block in which length to breadth ratio is 2 but height can be different.

· Normal size (nominal size)

· 9” ×4.” ×3“

· Architectural size (Working size)

· 81⅟16″ x 4⁵⁄₁₆” x 21⅟16″

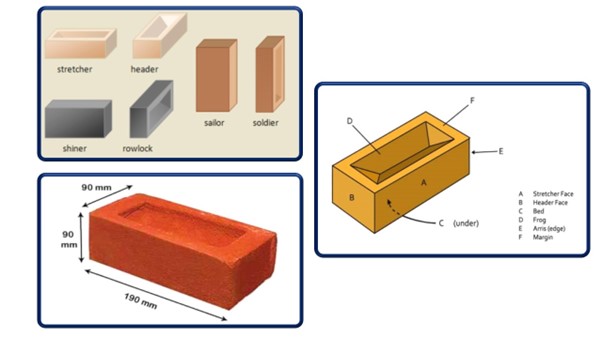

Technical Parts of Brick (Terms and Dimension)

Course-A course is a horizontal layer of bricks or stones.

Bed-It is the surface of stone perpendicular to the line of pressure. It indicates the lower surface of bricks or stones in each course.

The face-The exterior of the wall exposed to the weather is known as the face. The material used in the face of the wall is known as facing.

Header-It is a brick or stone which lies with its greatest length at right angles to the face of the work. in the case of stone, a masonry header is sometimes known as through stone. The course of brickwork in which all the bricks are laid as headers is known as header course.

Stretcher-It is a brick or a stone that lies with its longest side parallel to the face of the work. The course of brickwork in which all the bricks are laid as stretchers is known as the stretcher course.

Bond-This is the method of arranging bricks so that the individual units are tied together. Bonding is essential to eliminate continuous vertical joints both in the body as well as on the face of the wall.

CLOSE -It is the portion of the brick cut lengthwise in such a manner that it’s one long face remains uncut.

Frog-It is an indentation or depression on the top face of a brick made with the object of forming a key for the mortars. This reduces the weight of the brick also.

Coping-It is a course placed upon the exposed top of an external wall to prevent the seepage of water.

Bond Of Brick

- Stretcher Bond

- Header Bond

- English Bond

- Flemish Bond

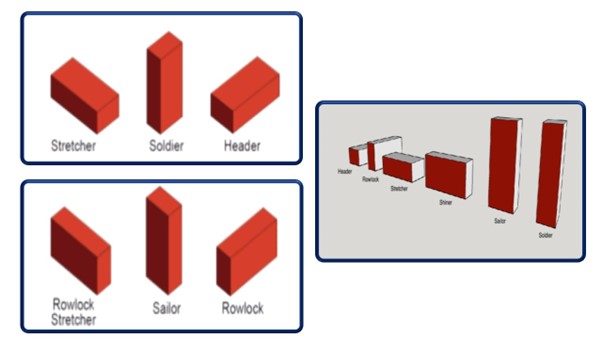

Orientation Of Brick

A brick has three dimensions: width (sometimes referred to as thickness), height and length. Although brick can be laid in six different orientations (see Figure 1), these dimensions as referenced apply to a brick laid as a stretcher. Height and length are sometimes called face dimensions, because these are the dimensions exposed when the brick is laid as a stretcher. Bricks are the subject of British Standard BS 3921.

Types Of Brick

- Burnt clay bricks

- Fly ash bricks

- Concrete bricks

- Engineering bricks

- Calcium silicate bricks

- Eco bricks

What Is AAC?

Autoclaved aerated concrete (AAC) is made with fine aggregates, cement, and an expansion agent that causes the fresh mixture to rise like bread dough. In fact, this type of concrete contains 80 percent air.

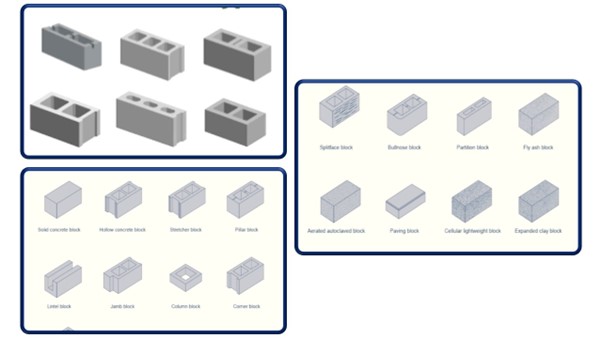

Different Between Block and Brick

The most important difference between blocks and bricks is in the size, composition, shape and weight. Blocks usually are bigger and lightweight and are made from concrete in comparison to brick. Blocks come in both solid and hollow format and are used where strength is important like a load-bearing wall.

Types Of Blocks

- Solid Concrete Blocks

- Hollow Concrete Blocks

- Stretcher Block

- Pillar Block

- Lintel Block

- Jamb Block

- Column Block

- Corner Block

- Split face Block

- Bullnose Block

- Partition Block

- Fly Ash Block

- Aerated Autoclaved Block

- Paving Block

- Cellular Lightweight Block

Some Important Segment

- FROG

- COURSE

- MORTAR JOINTS

- BATS

Upcoming Batches

Certifications

Brick Work Layout Certification Training

About Brick Work Layout Certification Training in Indore at Tech Cluster

Reviews