BBS (Bar Bending Schedule) Training in India

- Real-Time Experts Sessions

- LIVE Project

- Certification

- Affordable Fees

- Flexibility

- Placement Support

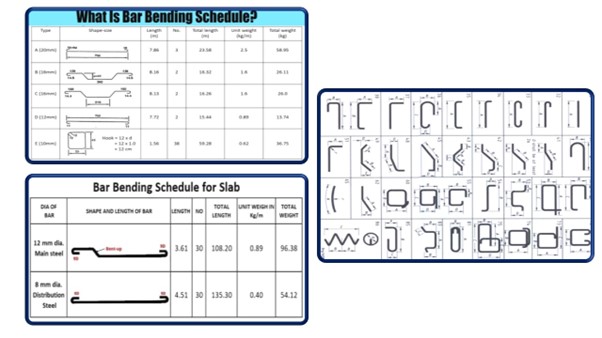

Bar bending schedule or schedule of bars is a tabular representation of reinforcement bar. It is generally represented for each type of R.C.C work. With the help of bar bending schedule the requirement of different length and sizes of bars may be known and can be arranged and bent-up during the time of construction.

Bar bending schedule generally describes the particulars of bars, shape of bending with sketches and total length and weight of the bars along with their numbers. Bar bending schedule is generally prepared while estimating a R.C.C work or structure.

Applications

From 1950 to 2019 lots of modifications and enhancements happening in our world. In 1950, three-storeyed buildings are high rise buildings now we are constructing a building with 200 floors+. There is a massive growth in the construction industry. Due to the vast increase in world population demands increased facilities, more need for space and more construction.

Father of Estimation B.N. Datta has given certain recommendations for the usage of steel in different components of buildings. But, he didn’t mention any values if we use more bars in a single structural member.

Course Highlights:

BBS (Bar Bending Schedule) Foundation :

- What Is Bar Bending Schedule

- Use Of Bar Bending Schedule

- Prepare BBS Of Footing

- Prepare BBS Of Column

- Advance BBS Of Beam

- BBS Of One-Way Slab

- BBS Of Two-Way Slab

- Create BBS Of Staircase

- BBS Of Pile and Pile Cap

- BBS Of Sunken Slab

Duration :

- 30 Hours Theory

- 25 Hours Practical

- 20 Hours Project work

Technical Features:

What Is Bar Bending Schedule

Bar Bending Schedule (BBS) is basically the representation of bend shapes and cut length of bars as per structure drawings. Calculation of the total quantity of TMT Steel Bar required for building construction is termed as Bar Bending Schedule. Steel Bar reinforce in concrete structure therefore the construction structure can withstand during the tension.

Use Of Bar Bending Schedule

• Bar Bending Schedule (BBS) helps to determine the quantity of steel required in the construction of your house. This helps to get an accurate estimation of steel

• Once the calculation of cutting and bending is done it reduces the wastage of steel and it becomes economic

Prepare BBS Of Footing

Bar Bending schedule plays a vital role in the construction of High-rise buildings. It is very important to learn Bar Bending Schedule for finding out the quantities of Steel reinforcement required for every component of the building.

Prepare BBS Of Column

- Always tie the column at the centre of each floor Since the axial loads & internal forces are maxim at top & bottom of the column.

- Always lap alternate bars

- Always lap top bar over the bottom bar

- Try to minimize the lap length and cutting of the bar as much as you can.

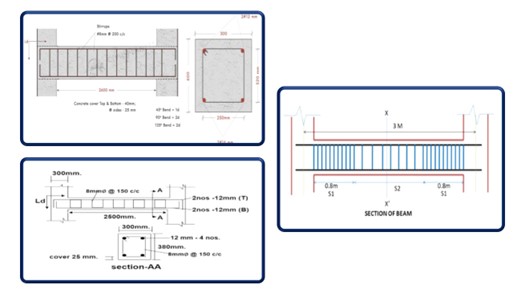

Advance BBS Of Beam

Beam (Straight beam) is a beam which connects the two footing in the substructure. Tie beam is provided when the two footings are in the same line. Strap Beam (inclined beam) is similar to tie beam but it connects two footings at a certain angle. Strap beam is laid when two footings are in different levels. Tie beam/ Strap beam are specifically located between pile caps and shallow foundations. their primary function is to force all shallow foundations or pile caps to have approximately the same

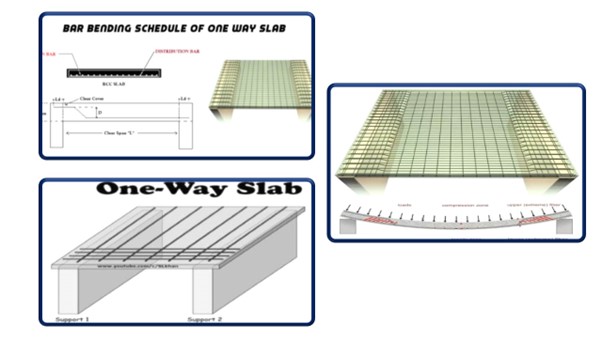

BBS Of One-Way Slab

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction. The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e., in the direction along its shorter span Due to the huge difference in lengths, the load is not transferred to the shorter beams. Main reinforcement is provided in shorter span and distribution reinforcement in a longer span.

BBS Of Two-Way Slab

Two-way slab is a slab supported by beams on all the four sides and the loads are carried by the supports along with both directions, it is known as two-way slab. In two-way slab, the ratio of longer span (l) to shorter span (b) is less than 2.

In two-way slabs, the load will be carried in both the directions. So, the main reinforcement is provided in both directions for two-way slabs.

Create BBS Of Staircase

Stairs provide access to the various floors of the building. The stair consists of a series of steps with landings at appropriate intervals. The stretch between the two landings is called flight. The Space, where stairs are provided is called a staircase.

To make it easy in understanding, I am calculating the quantities of a staircase by dividing it into components.

Components of Staircase: –

• Waist slab

• Flight

• Landing

• Step

• Tread

• Riser

BBS Of Two-Way Slab

Two-way slab is a slab supported by beams on all the four sides and the loads are carried by the supports along with both directions, it is known as two-way slab. In two-way slab, the ratio of longer span (l) to shorter span (b) is less than 2.

In two-way slabs, the load will be carried in both the directions. So, the main reinforcement is provided in both directions for two-way slabs.

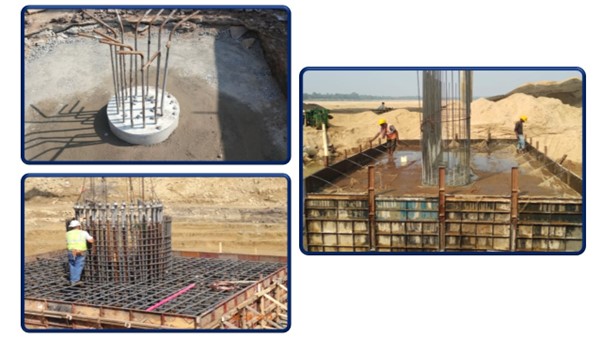

BBS Of Pile and Pile Cap

A Pile foundation is a type of deep foundation. A Pile foundation is made of long columnar elements of steel or reinforced concrete. When the depth of the foundation is more than three times its breadth then it is called a pile. A Pile foundation is used to transfer the loads from the superstructures. A Pile foundation is used for large structures.

Types of Pile Foundation

1. Bored Piling

2. Driven Piling

3. Screw Piling

4. Mini Piling

5. Sheet Piling

BBS Of Sunken Slab

The slab which is provided below the washrooms to hide the sewage pipes or sewerage pipes is called Sunken slab. In this type, the pipes that carry water are concealed below the floor. Special care has to be taken to avoid leakage problems. After casting sewage pipes in the slab, the slab is filled with coal or broken pieces of bricks. There are two types of sunken slab.

The slab which is provided below the normal floor level at a depth of 200mm to 300 mm and filled with broken pieces of bricks is called Sunken slab.

Upcoming Batches

Certifications

BBS (Bar Bending Schedule) Certification Training

About BBS (Bar Bending Schedule) Certification Training in Indore at Tech Cluster

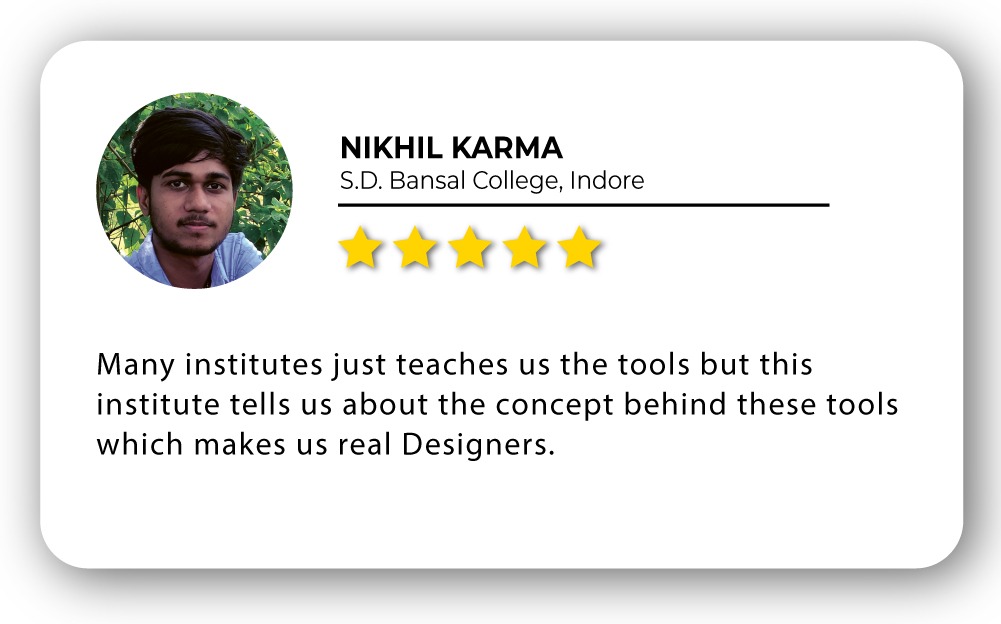

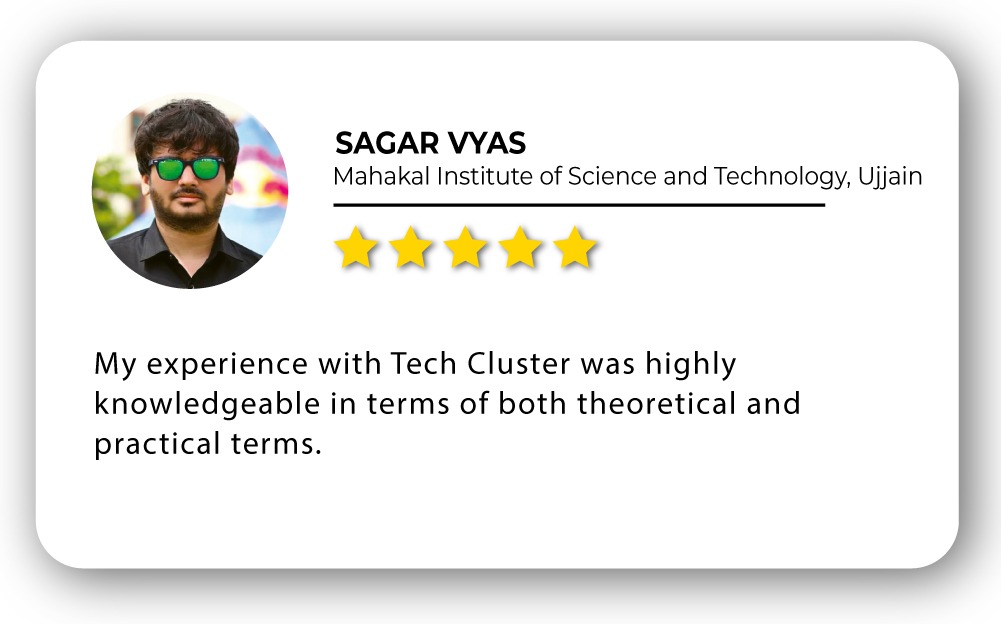

Reviews