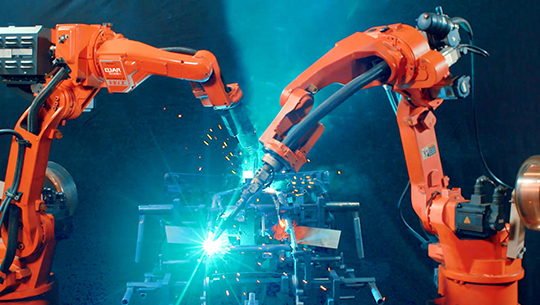

Welding Technology Training in India

- Real-Time Experts Sessions

- LIVE Project

- Certification

- Affordable Fees

- Flexibility

- Placement Support

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal).

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized.

Tech Cluster is an institute which provides Welding Technology Training in Indore and offers chances to avail a great opportunity to learn the tool from basic to advanced level. Our expert faculties cover all the important factors of Welding Technology Training for beginners and intermediates. With our expert guidance students can excel in their career and earn good. After which you can find good opportunities in MNC Industries like Eicher and other automobile industries.

Course Highlights:

Welding Technology Foundation :

- Introduction to Welding Technology

- Types of Welding

- Welding Terminology

- Types of Welding Joints

- Types of weld

- Parts of Welded Joint

- Parts of Welds

- Welding Symbols

Duration :

- 45 Hours Theory

- 45 Hours Practical

- 20 Hours Project work

Technical Features:

Introduction to Welding Technology

Welding is a fabrication process used to join materials, usually metals or thermoplastics, together. During welding, the pieces to be joined (the workpieces) are melted at the joining interface and usually a filler material is added to form a pool of molten material (the weld pool) that solidifies to become a strong joint.

In contrast, Soldering and Brazing do not involve melting the workpiece but rather a lower-melting-point material is melted between the workpieces to bond them together.

Types of Welding

There are many different types of welding processes and in general they can be categorized as:

Arc Welding: A welding power supply is used to create and maintain an electric arc between an electrode and the base material to melt metals at the welding point. In such welding processes the power supply could be AC or DC, the electrode could be consumable or non-consumable and a filler material may or may not be added.

Gas Welding: In this method a focused high temperature flame generated by gas combustion is used to melt the workpieces (and filler) together. The most common type of gas welding is Oxy-fuel welding where acetylene is combusted in oxygen.

Resistance Welding: Resistance welding involves the generation of heat by passing a high current (1000–100,000 A) through the resistance caused by the contact between two or more metal surfaces where that causes pools of molten metal to be formed at the weld area. The most common types of resistance welding are Spot-welding (using pointed electrodes) and Seam-welding (using wheel-shaped electrodes).

Energy Beam Welding: In this method a focused high-energy beam (Laser beam or electron beam) is used to melt the workpieces and thus join them together.

Solid-State Welding: In contrast to other welding methods, solid-state welding processes do not involve the melting of the materials being joined. Common types of solid-state welding include; ultrasonic welding, explosion welding, electromagnetic pulse welding, roll welding, friction welding (including friction-stir- welding), etc.

Welding Terminology

There is some special technical vocabulary (or language) that is used in welding. The basic terms of the welding language include:

Filler Material: When welding two pieces of metal together, we often have to leave a space between the joint. The material that is added to fill this space during the welding process is known as the filler material (or filler metal).

Welding Rod: The term welding rod refers to a form of filler metal that does not conduct an electric current during the welding process. The only purpose of a welding rod is to supply filler metal to the joint. This type of filler metal is often used for gas welding.

Electrode: In electric-arc welding, the term electrode refers to the component that conducts the current from the electrode holder to the metal being welded. Electrodes are classified into two groups: consumable and non-consumable.

Flux: Before performing any welding process, the base metal must be cleaned form impurities such as oxides (rust). Unless these oxides are removed by using a proper flux, a faulty weld may result. The term flux refers to a material used to dissolve oxides and release trapped gases and slag (impurities) from the base metal such that the filler metal and the base metal can be fused together. Fluxes come in the form of a paste, powder, or liquid. Different types of fluxes are available and the selection of appropriate flux is usually based on the type of welding and the type of the base metal.

Types of Welded Joints

The weld joint is where two or more metal parts are joined by welding. The five basic types of weld joints are the butt, corner, tee, lap, and edge.

Butt Joint: it is used to join two members aligned in the same plane. This joint is frequently used in plate, sheet metal, and pipe work.

Corner and Tee Joints: these joints are used to join two members located at right angles to each other. In cross section, the corner joint forms an L-shape, and the tee joint has the shape of the letter T.

Lap Joint: this joint is made by lapping one piece of metal over another. This is one of the strongest types of joints available; however, for maximum joint efficiency, the overlap should be at least three times the thickness of the thinnest member of the joint.

Edge Joint: it is used to join the edges of two or more members lying in the same plane. In most cases, one of the members is flanged, as seen in the figure. This type is frequently used in sheet metal work for joining metals 1/4 inch or less in thickness that are not subjected to heavy loads

Types of Welds

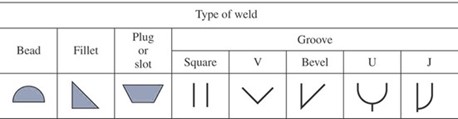

There are many types of welds. The most common types are the bead, surfacing, plug, slot, fillet, and groove.

- A weld Bead is a weld deposit produced by a single pass with one of the welding processes. A weld bead may be either narrow or wide, depending on the amount of transverse oscillation (side-to-side movement) used by the A weld bead made without much weaving motion is often referred to as a stringer bead. On the other hand, a weld bead made with side-to-side oscillation is called a weave bead.

- Several weld beads applied side-by-side are usually used in Surfacing which is a welding process used to apply a hard, wear-resistant layer of metal to surfaces or edges of worn- out parts.

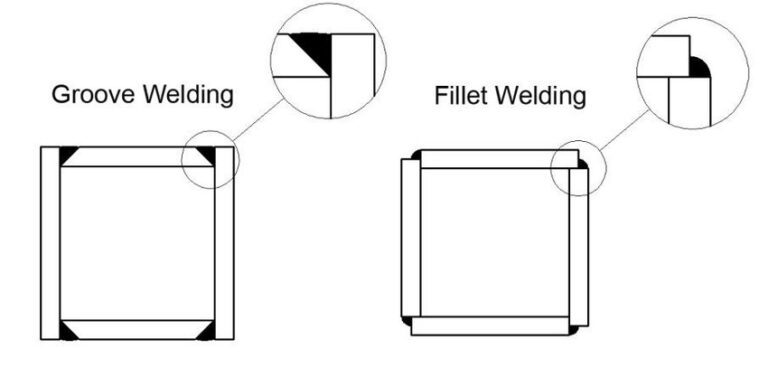

- A Fillet weld is triangular in shape and this weld is used to join two surfaces that are at approximately right angles to each other in a lap, tee, or comer joint.

- Plug and Slot welds are welds made through holes or slots in one member of a lap These welds are used to join that member to the surface of another member that has been exposed through the hole.

- Groove welds (also may be referred to as Butt welds) are simply welds made in the groove between two members to be joined. The weld is adaptable to a variety of butt joints.

Parts of Welded Joints

While there are many variations of joints, the parts of the joint are described by standard terms-

- The root of a joint is that portion of the joint where the metals are closest to each other. As shown in the figure, the root may be a point, a line, or an area, when viewed in cross section.

- A groove is an opening or space provided between the edges of the metal parts to be welded.

- Root penetration refers to the depth that a weld extends into the root of the joint. Root penetration is measured on the center line of the root cross section.

- Joint penetration refers to the minimum depth that a groove weld extends from its face into a joint, exclusive of weld.

- Weld reinforcement is a term used to describe weld metal in excess of the metal necessary to fill a joint. The reinforcement needs to be grinded in some cases depending on the intended use of the joint.

Parts of Welds

It is important to be familiar with the terms used to describe a weld. The figure shows the parts of groove weld and fillet welds.

- The face is the exposed surface of a weld on the side from which the weld was

- The toe is the junction between the face of the weld and the base

- The root of a weld includes the points at which the back of the weld intersects the base metal

- In a fillet weld, the leg is the portion of the weld from the toe to the

- In a fillet weld, the throat is the distance from the root to a point on the face of the weld along a line perpendicular to the face of the weld. Theoretically, the face forms a straight line between the toes.

- The size of a fillet weld refers to the length of the legs of the The two legs are assumed to be equal in size unless otherwise specified.

Welding Symbols

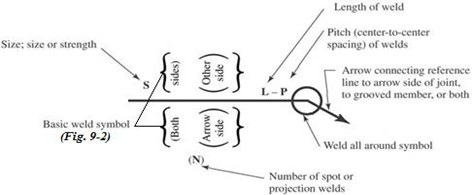

Welding symbols are used on drawings to indicate the type and specifications of the weld.

- The figure shows the American Welding Society (AWS) standard welding The most important features of the welding symbol are illustrated.

- The table shows the Basic weld symbol for the different types of welds.

Upcoming Batches

Certifications

Welding Technology Certification Training

About Welding Technology Certification Training in Indore at Tech Cluster

Reviews