Jigs and Fixture Design Training in India

- Real-Time Experts Sessions

- LIVE Project

- Certification

- Affordable Fees

- Flexibility

- Placement Support

Course Highlights:

Jigs and Fixture Design Foundation :

- What Is Jig & Fixture Design?

- Jigs vs. Fixtures: What’s the Difference?

- Types of Jigs and Fixtures

- Jig Construction

- Fixture Construction

Duration :

- 45 Hours Theory

- 45 Hours Practical

- 20 Hours Project work

Technical Features:

What Is Jig & Fixture Design?

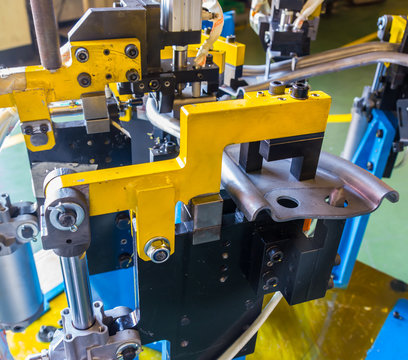

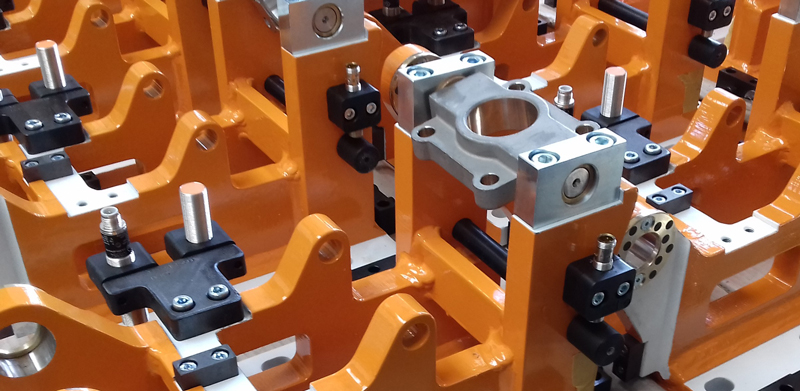

Jigs and fixtures are manufacturing tools that are used to produce identical and interchangeable components. These work holding and tool guiding devices are designed for use in the machining and assembly of parts.

To get the greatest benefit from jigs and fixtures, a basic understanding of their construction is necessary. Jigs and fixtures are identified one of two ways: either by the machine with which they are identified or by their basic construction. A jig, for instance, may be referred to as a “drill jig.” But if it is made from a flat plate, it may also be called a “plate jig.” Likewise, a mill fixture made from an angle plate may also be called an “angle-plate fixture.” The best place to begin a discussion of jig and fixture construction is with the base element of all work holders, the tool body.

Jigs vs. Fixtures: What's the Difference?

While jigs and fixtures work together, these are two distinct tools used in mass production processes. The two terms are often used incorrectly as synonyms but serve different purposes.

A jig controls and guides the cutting tool to work at a predefined location on a workpiece. Fixtures are used for supporting and locating a workpiece. Fixtures do not guide the tool on a workpiece like a jig.

Jigs are typically lighter than fixtures, which need additional force to stand up to cutting force and vibration. While fixtures require clamping and accessories, a jig can be held or fixed to a table depending on the application.

Types of Jigs and Fixtures

Types of Jigs

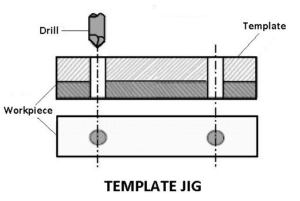

- Template Jig

- Plate Jig

- Channel Jig

- Diameter Jig

- Leaf Jig

- Ring Jig

- Box Jig

Types of Fixtures

- Turning Fixtures

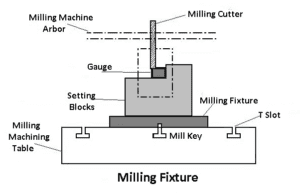

- Milling Fixtures

- Broaching Fixtures

- Grinding Fixtures

- Boring Fixtures

- Tapping Fixtures

- Duplex Fixtures

- Welding Fixtures

- Assembly Fixtures

Jig construction

A jig is a type of custom-made work holding device that is used to control the location and speed of parts and other equipment. In the CNC machining process, a jig often locates the workpiece in an appropriate position and cutting tool. Guides to maintain the correct relationship between operation, work, and cutter. When the jig moves, the instrument remains stationary. The machining part is usually secured to the jig by clamping.

The most common jigs are drill and boring jigs. These devices are basically the same. The difference lies in the size, types, and placement of drill bushes. Boring jigs usually have large bushes. These bushes may also have internal oil grooves to keep the boring bar lubricated.

Fixture construction

- The fixator is a work-holding device used to safely locate, support, and mount the machine in a safe position, to ensure that the workpiece fixed in the fixture maintains conformity and interchangeability can.

- When the fixture moves, the instrument moves relative to the part. The fixtures can ensure that the part is stable, simplifying the mounting of the workpiece so that a quick transition from part to part and smooth operation can be realized.

- What distinguishes the jig does not guide the instrument.

Upcoming Batches

Certifications

Jigs and Fixture Design Certification Training

About Jigs and Fixture Design Certification Training in Indore at Tech Cluster