REVERSE ENGINEERING

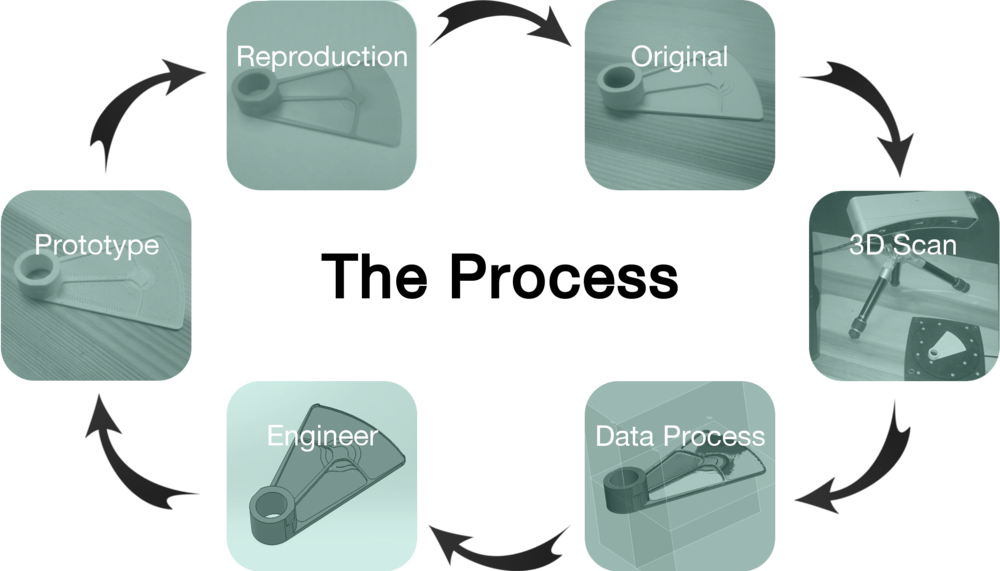

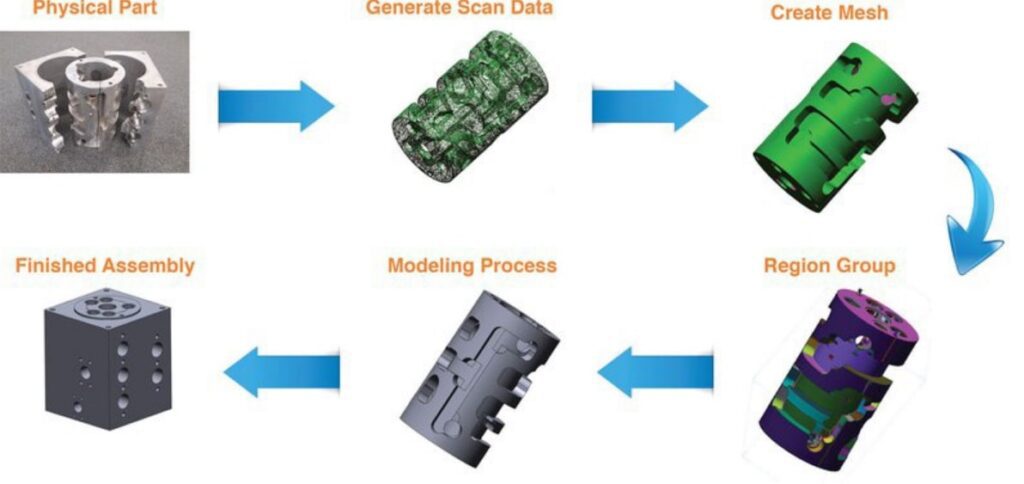

Reverse engineering (also known as backwards engineering or back engineering) is a process or method through which one attempts to understand through deductive reasoning how a device, process, system, or piece of software accomplishes a task with very little (if any) insight into exactly how it does so.

Reverse engineering is applicable in the fields of computer engineering, mechanical engineering, design, electronic engineering, software engineering, chemical engineering, and systems biology.

Applications

➢ Design– Production and design companies applied Reverse Engineering to practical craft-based manufacturing processes. The companies can work on “historical” manufacturing collections through 3D scanning, 3D re-modelling and re-design. In 2013 Italian manufactures Baldi and Savio Firmino together with University of Florence optimized their innovation, design, and production processes.

➢ Product security analysis– That examines how a product works by determining the specifications of its components and estimate costs and identifies potential patent infringement. Also part of product security analysis is acquiring sensitive data by disassembling and analyzing the design of a system component. Another intent may be to remove copy protection or to circumvent access restrictions.

➢ Competitive technical intelligence– That is to understand what one’s competitor is actually doing, rather than what it says that it is doing.

➢ Saving money– Finding out what a piece of electronics can do may spare a user from purchasing a separate product.

➢ Interfacing– Reverse engineering can be used when a system is required to interface to another system and how both systems would negotiate is to be established. Such requirements typically exist for interoperability.

Course Highlights:

➢ Introduction or Reverse Engineering

➢ Jigs & Fixture

➢ Using Gauges /measuring Instruments

➢ Lubricants And Cutting Fluids

➢ Drilling & Turning Machine processes

➢ Cad Drawing Convert Into DXF For CNC

Duration

- 25 Hours Theory

- 25 Hours Practical

- 20 Hours Project work

Technical Feature

➢ Reverse-engineering is the act of dismantling an object to see how it works. It is done primarily to analyze and gain knowledge about the way something works but often is used to duplicate or enhance the object. Many things can be reverse-engineered, including software, physical machines, military technology and even biological functions related to how genes work.

✓ Jig & Fixture

➢ JIG:- A jig is a type of custom – made tool used to control the location and motion of parts or other tools. ▪ A jig’s primary purpose is to provide repeatability accuracy and interchangeability in the manufacturing of product

➢ FIXTURE :- A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability.

- Measuring Tape.

➢ Plain Type Gauge.

➢ Snap Gauges or Gap Gauges. ➢ Ring Type Gauge.

➢ Limit Type Gauge.

➢ Pin Type Gauge.

➢ Caliper Type Gauge.

➢ Feeler Type Gauge.

➢ Screw Pitch Gauges.

- Level.

- Ruler.

- Pressure Gauge. • Thermometer. • Clocks.

- Speedometer. • Measuring Cups.

➢ Engine oils. Petrol (Gasolines) engine oils. Diesel engine oils.

➢ Automatic transmission fluid.

➢ Gearbox fluids.

➢ Brake fluids.

➢ Hydraulic fluids.

➢ Air conditioning compressor oils.

➢ Turning

➢ Drilling/Boring/Reaming

➢ Milling

➢ Grinding

➢ Planing

➢ Sawing

➢ Broaching

➢ We specialize in software solutions for the woodworking industry and have developed AutoCAD-based tools to analyze virtually any 3D solid and convert them into manufacturable parts. This works well for cabinet parts, fixtures, millwork or die walls, single parts, countertops, nurses stations, etc. Basically, flat panel processing with a flat-table router or saw / point-to-point machining center.